Kaizen is a fundamental concept that has supported Japanese manufacturing and is now adopted worldwide in business. This article introduces its meaning and the background of Kaizen in Japan in a clear and accessible way.

What is Kaizen?

Kaizen in Japanese means “to make better,” and in business it refers to the ongoing effort to improve work processes. Internationally, it is written as “Kaizen” and has spread globally, especially in manufacturing.

Kaizen is characterized by not requiring major investments or large-scale reforms, but instead focusing on small, daily improvements. For example, simply adjusting the height of a workbench can reduce worker fatigue, and reorganizing tool placement can shorten work time. These small changes eventually lead to large organizational gains.

The core features of Kaizen can be summarized as follows:

| Aspect | Description |

|---|---|

| Meaning | Continuous accumulation of small improvements |

| Characteristics | Driven by the workplace, fearless of failure |

| Purpose | Elimination of waste, efficiency, quality enhancement |

| Outcome | Long-term organizational growth |

The essence of Kaizen lies in the attitude of “continuing improvement”, and this is why it is valued globally.

The Background of Kaizen in Japan

The roots of Kaizen in Japan lie in the post-war era, when resources were scarce and economic recovery was critical. Unlike the West, which focused on mass production, Japanese companies needed to balance efficiency with quality. As a result, they fostered a system where workplace wisdom and small improvements became the foundation of growth.

Japanese society itself values ingenuity and efficiency. In schools and community activities, children are encouraged to “find better ways.” This cultural foundation supports Kaizen in the workplace, making it naturally accepted.

The distinction between Japan and the West can be summarized as:

| Aspect | Japan | Western Countries |

|---|---|---|

| Reform method | Small, step-by-step accumulation | Large-scale reforms |

| Main actors | Frontline employees | Executives or special teams |

| Focus | Continuity and stability | Immediate results |

| Social background | Resource scarcity | Resource abundance, mass production |

Kaizen is often described as “a uniquely Japanese management philosophy.”

The Basic Principles of Kaizen

Three core principles guide Kaizen:

| Principle | Description |

|---|---|

| Small changes | Focus on everyday improvements rather than large reforms |

| Participation by all | Everyone, from executives to frontline workers, takes part |

| Continuity | Not one-off but repeated efforts to sustain improvement |

Among these, “participation by all” is especially important. Kaizen is not just the responsibility of management—the voice of the workplace is central. Small suggestions from employees, when accumulated, generate significant results across the organization.

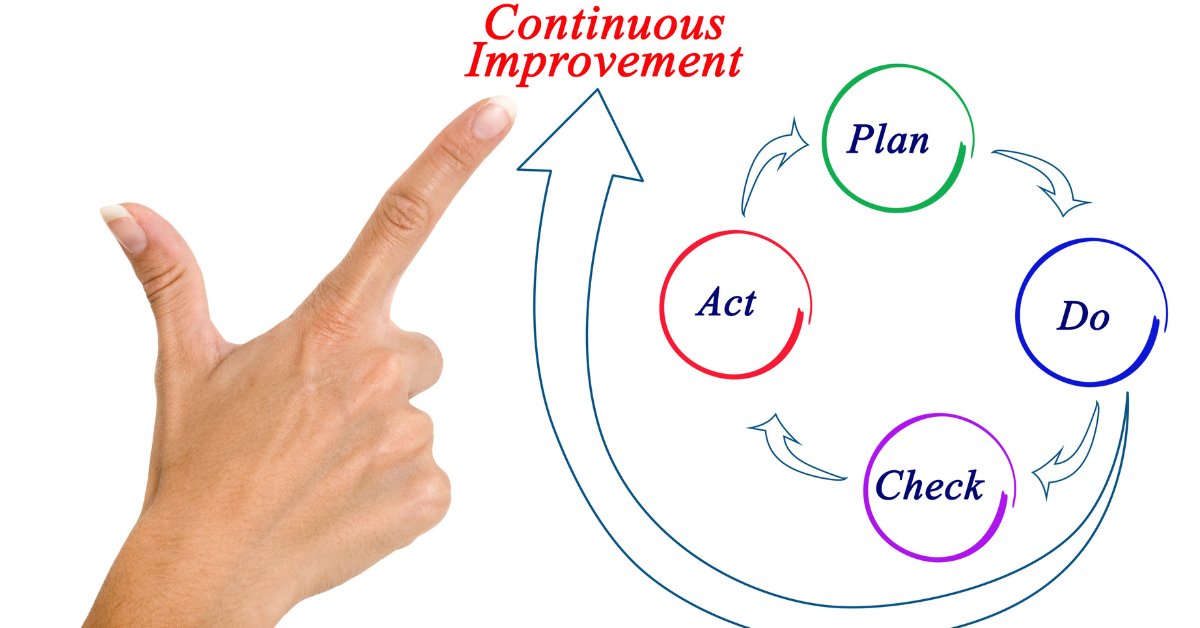

Kaizen and the PDCA Cycle

Kaizen is closely linked with the PDCA Cycle:

Plan → Do → Check → Act

Repeating this cycle steadily improves both efficiency and quality.

For instance, in manufacturing, if defects occur, the cause is analyzed, countermeasures are planned, implemented, evaluated, and then refined again. This cycle is also applied in healthcare, education, and public services, supporting better outcomes.

| Step | Example |

|---|---|

| Plan | Analyze problems and plan improvements |

| Do | Implement improvements on a small scale |

| Check | Evaluate the results |

| Act | Apply lessons learned and move to the next cycle |

The repetition of PDCA is the foundation that sustains the Kaizen culture.

What Foreigners Should Understand About Kaizen

For foreigners working in Japan, there are three key aspects to understand:

- It is driven bottom-up, not top-down

- Failure is accepted as part of the process

- Emphasis is on long-term accumulation, not quick results

Japanese Kaizen values persistence more than instant outcomes. For those from cultures that prioritize short-term results, this may feel different. However, understanding this perspective is essential for collaborating effectively in Japanese organizations.

Moreover, Kaizen is not only about efficiency. It also provides a continuous learning process that fosters personal growth. Employees gain problem-solving skills and a sense of ownership by contributing to improvements.

Concrete Examples of Kaizen

There are many successful cases of Kaizen in Japanese organizations:

- In automotive manufacturing, workers rearranged component placement to reduce motion and save time.

- In hospitals, changes in reception procedures reduced patient waiting times.

- In retail, reorganizing store shelves improved inventory management and boosted sales.

These examples show that small, workplace-driven ideas can generate large results without heavy investment.

| Field | Improvement | Result |

|---|---|---|

| Manufacturing | Reorganizing component placement | Shorter task time, higher productivity |

| Healthcare | Improving reception flow | Reduced waiting time, higher patient satisfaction |

| Retail | Adjusting shelf layout | More efficient stock management, sales growth |

Conclusion

Kaizen, born from Japanese manufacturing, is the philosophy of “continuous small improvements.” It has since spread globally across industries.

The greatest strength of Kaizen is the mindset of accumulating small changes over time, which creates sustainable growth.

For foreigners working in Japan, understanding and adopting this Kaizen mindset can lead to better teamwork, smoother collaboration, and more effective work practices.